Projects

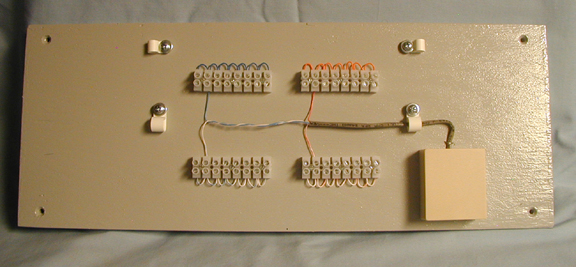

Telephone Patch Panel v1.2:

Optional Whole-House ADSL Filter:

Optional Whole-House ADSL Filter:

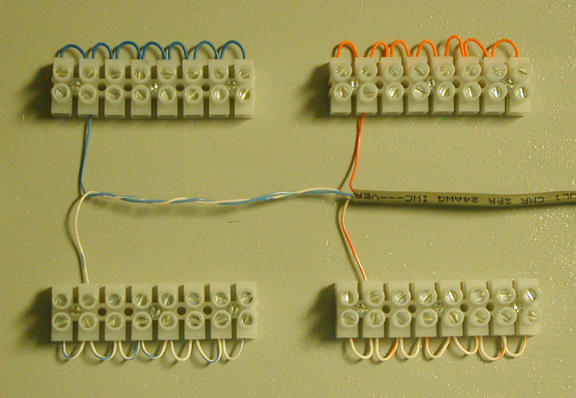

Center Close-up Diagram PDF (Actual Size)

This panel would be normally located where the landline telephone cable enters your house. The panel is roomy, and permits maintenance using common hand tools, except for a type of wire stripper (see Important Tool, below). The panel mounting holes are spaced at 16 inches for wall studs. This panel is only for use with household telephone cabling with or without ADSL, not for Ethernet network cabling, of course.

I designed this after a day of helping a neighbor who was having telephone trouble (their line was noisy, incoming rings were very brief and calls could not be made or received).

Reluctant to get into their old house cabling, I disconnected all their devices and connected a standard phone to one of their jacks; the problem continued. Following phone company procedures, I took the phone to their outdoor termination box, disconnected the house wiring, and connected the phone to the incoming line; the phone worked correctly.

Down in their basement, I found that there were five cables connected by dangling 66 punchdown blocks. The house used a mixture of home-run cables and series connections. I cut off the punchdown blocks, and installed a screw-terminal jack box. Only the single home-run cable to the cordless base station was connected. Those phones now worked correctly. The rest was a matter of re-connecting lines one at a time until the problem returned, and it did with a series line of 4 jacks. I replaced two of their old lines and jack boxes with home-run 24AWG Cat3 cable, and just left their 3 unused lines disconnected. Lastly, I labelled the known lines at the junction jack box.

In the end, finding the bad line would have been a lot easier if they had used home-run cabling without punch-down blocks, and if the cables had been labelled. Certainly, some punch-down connections can be re-punched, but I just feel that they're prone to intermittant connections and difficult to troubleshoot, especially in a basement environment.

Important Tool: Stripping solid-conductor wire requires a tool that won't nick the conductor. Depending on the depth of a nick, damaged solid conductors will break when bent, and the break may be intermittant; troubleshooting a network with this kind of problem is a nightmare. If all the cabling was stripped improperly, every termination would need to be done over. I've seen builders using pen knives and box cutters on telephone cabling ... and even AC electrical cables. A good stripping tool for 30-20 gauge wire is the Hakko CSP-30-1 (inexpensive, available at Amazon).

Cabling: These days, unshielded twisted-pair (UTP) Cat5 or Cat5e cables are used for landline telephone cabling. These are 4-pair cables, although (oddly more expensive) 2-pair cables are available. A typical home installation uses one pair for Line 1 and one pair for Line 2 (usually Blue and Orange pairs, although it doesn't matter which color pairs you use, as long as you're consistent). Even if you're only using Line 1, it's best to cable both lines in your phone network (the two unused pairs are wrapped around the cable body). 2-pair Cat3 cabling may also be used, but Cat3 cabling is generally obsolete. Telephone cabling, as well as Ethernet cabling, should be kept at least 2-feet away from AC power cables and fluorescent lights; it's OK to cross a power cable at 90 degrees, if necessary, but network cables should never run close alongside (parallel to) power cables.

Try to avoid sharp 90-degree cable bends, as these will cause impedance changes. Rather, make a 90-degree bend of Cat5 cable with a circle diameter of 4 inches minimum. You may recall the basis of this precaution as Minimum Bend Ratio, and is of particular importance with fiber optic cables.

When you use cable clamps, don't allow them to compress or distort the cable. It's best to use clamps or staples merely as loose or gently snug cable guides, and this applies to power cabling as well. A crushing clamp on an Ethernet or telephone cable will produce an impedance change (signal loss) which can only be detected with a time-domain reflectometry (TDR) cable tester. Excess cabling should not be coiled but should be routed to one side with a single U loop.

For telephone jack boxes, you can use standard RJ-14 screw-terminal boxes with either 4 or 6-conductor jacks. If you'd like faster and easier assembly, modular RJ-14 punchdown boxes/jacks/covers are available at higher cost. You can also run a telephone and an Ethernet cable in a single box with separate RJ-14 and RJ-45 jacks. Don't even think about combining telephone and Ethernet in a single 4-pair cable: While this is physically possible, crosstalk will disrupt both telephone and Ethernet. Telephone and Ethernet must be run using two separate cables (and two jacket colors, if possible). It's also best to keep telephone and Ethernet cabling runs separated by at least 12 inches whenever possible.

Final Thought: The overall load of a phone line is important. You may remember when Bell Telephone required the Ringer Equivalence Number (REN) of each device on your network, and the total could not exceed 5. One of the old-style phones typically had a REN of 1, and this meant that you could have no more than 5 of these phones connected. Don't be surprised if even a telephone technician hasn't heard of REN these days. [ I had a technician use an ohmmeter on a line without disconnecting all the devices, and incorrectly reported that the line had a short. ] You'll find the REN number on the back of every telephone device, even today; most new devices have a REN of less than 1.

If you think you might like to install a panel like ours, all the information you might need is in the above PDF documents. If you're not terribly interested in building one yourself, we do have a couple of panels pre-made and ready to ship. These panels are primed and enamelled with all components as shown for $110.91 plus shipping. We can include the PS-15 ADSL Filter on your panel for $152.90 plus shipping. [ The PS-15 ADSL filter allows you to dispense with all the single filters you may have on your phones and FAX. ]

We're happy to have your input on our design, or any comments you may have for changes or improvements you might like to see. Thanks!

©Copyright 2002, 2011

Evergreen Computer Services